vickers hardness test astm|vickers hardness testing formula : purchase 1.1 These test methods cover the determination of the Vickers hardness and Knoop hardness of metallic materials by the Vickers and Knoop indentation hardness principles. This standard provides the requirements for Vickers and Knoop hardness machines and the . web16 de jun. de 2019 · Euphoria follows a group of high schoolers as they explore the worlds of drugs, sexuality, and violence.

{plog:ftitle_list}

WEBAt Truong Tien, the menu is incredibly diverse, ranging from appetizers, main courses to desserts, ensuring you have a satisfying meal. Some notable dishes at the restaurant include: bun hen (baby mussel noodle soup), bun bo Hue (Hue-style beef noodle soup), banh bot loc (clear shrimp and pork dumplings), banh nam (flat rice dumplings with .

1.1 These test methods cover the determination of the Vickers hardness and Knoop hardness of metallic materials by the Vickers and Knoop indentation hardness principles. This standard provides the requirements for Vickers and Knoop hardness machines and the .1. Scope. 1.1 This test method covers the determination of the Vickers hardness of metallic materials, using applied forces of 1 kgf to 120 kgf,2 the verification of Vickers hardness .

NOTE 1—The Vickers and Knoop hardness numbers were originally standard provides the requirements for Vickers and Knoop defined in terms of the test force in kilogram-force (kgf) and the surface hardness machines and the .The Vickers test can be used for all metals and has one of the widest scales among hardness tests. The unit of hardness given by the test is known as the Vickers Pyramid Number (HV) or . Standard Test Methods for Vickers Hardness and Knoop Hardness of Metallic Materials. 1.1 These test methods cover the determination of the Vickers hardness and Knoop .

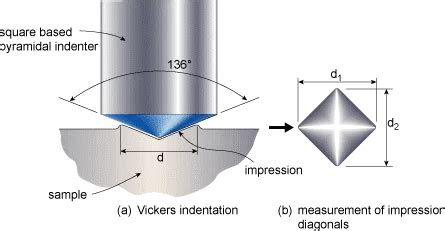

ASTM E384 Standard Test Method for Knoop and Vickers Hardness of Materials -- eLearning Course. Price: 5 . Add to Cart. About the Course. This test method covers determination of the Knoop and Vickers hardness of materials, the verification of Knoop and Vickers hardness testing machines, and the calibration of standardized Knoop and Vickers . 5.1 For advanced ceramics, Vickers indenters are used to create indentations whose surface-projected diagonals are measured with optical microscopes. The Vickers indenter creates a square impression from which two surface-projected diagonal lengths are measured. Vickers hardness is calculated from the ratio of the applied force to the area of contact of the .

Note 1: The Vickers and Knoop hardness numbers were originally defined in terms of the test force in kilogram-force (kgf) and the surface area or projected area in millimetres squared (mm 2).Today, the hardness numbers are internationally defined in terms of SI units, that is, the test force in Newtons (N). However, in practice, the most commonly used force .

Note 1: The Vickers and Knoop hardness numbers were originally defined in terms of the test force in kilogram-force (kgf) and the surface area or projected area in millimetres squared (mm 2).Today, the hardness numbers are internationally defined in terms of SI units, that is, the test force in Newtons (N). However, in practice, the most commonly used force . Standard Test Method for Knoop and Vickers Hardness of Materials E0384-11E01 ASTM|E0384-11E01|en-US Standard Test Method for Knoop and Vickers Hardness of Materials Standard E384 Standard Test Method for Knoop and Vickers Hardness of Materials > new BOS Vol. 03.01 Committee E04 $ 129.00 In stockVickers hardness test sangat ideal untuk pengujian semua logam dan karenanya merupakan metode dengan rentang aplikasi terluas.Hardness test method menurut Vickers dijelaskan dalam standar ISO 6507 (Bahan logam – Uji kekerasan Vickers – Bagian 1: Metode uji) dan ASTM E384 (Metode Uji Standar untuk Kekerasan Mikroindentasi Bahan terhadap Vickers .

Standardized optical hardness testing methods include the Brinell hardness test (ISO 6506, ASTM E10), Knoop hardness test (ISO 4545, ASTM E92, ASTM E384) and Vickers hardness test (ISO 6507, ASTM E92, ASTM E384). Alternatively, methods with dynamic force application can also be used within the scope of hardness testing.

Standard Test Method for Knoop and Vickers Hardness of Materials E0384-10E02 ASTM|E0384-10E02|en-US Standard Test Method for Knoop and Vickers Hardness of Materials Standard E384 Standard Test Method for Knoop and Vickers Hardness of Materials> new BOS Vol. 03.01 Committee E04 $ 129.00 In stockNote 1: The Vickers and Knoop hardness numbers were originally defined in terms of the test force in kilogram-force (kgf) and the surface area or projected area in millimetres squared (mm 2).Today, the hardness numbers are internationally defined in terms of SI units, that is, the test force in Newtons (N). However, in practice, the most commonly used force units are kilogram . 1.4 This test method covers Vickers hardness tests made utilizing test forces ranging from 9.807 × 10-3 N to 1176.80 N (1 gf to 120 kgf), and Knoop hardness tests made utilizing test forces from 9.807 × 10-3 N to 19.613 N (1 gf to 2 kgf).. 1.5 Additional information on the procedures and guidance when testing in the microindentation force range (forces = 1 kgf) .In the Rockwell hardness test, a differential-depth method, the residual depth of the indent made by the indenter, is measured.In contrast, the size of the indentation is measured in the Brinell, Vickers and Knoop optical test methods.. The deeper a defined indenter penetrates the surface of a specimen with a specified test load, the softer the material that is being tested.

Standard Test Method for Knoop and Vickers Hardness of Materials E0384-11 ASTM . Standard Test Method for Vickers Hardness Testing. 1.4 This test method includes an analysis of the possible sources of errors that can occur during Knoop and Vickers testing and how these factors affect the accuracy, repeatability, and reproducibility of test .

Procedure 7.1 Magnitude of Test Load—Test loads of 1 kgf to 120 5 ASTM Е 92 TABLE 6 Correction Factors for Use in Vickers Hardness Tests Made on Cylindrical Surfaces TABLE S Correction Factors for Use in Vickers Hardness Tests Made on Cylindrical Surfaces (One diagonal parallel to axis) (Diagonals at 45° to the axis) Convex Surface Convex .among Brinell hardness, Vickers hardness, Rockwell hardness, Rockwell superficial hardness, and Knoop hardness of copper. 1.8 Conversion Table 8 presents data on the relationshipVickers hardness testing is carried out to standards such as ASTM E384 or ISO 6507 which has four parts describing the test itself, calibration and hardness tables. 9.11.2 Brinell hardness test An alternative method is the Brinell hardness test, which uses a hardened steel (or tungsten carbide) ball indenter with a diameter D of, usually, 10 mm.

Standards: DIN EN ISO 6506 / ASTM E10 Brinell Methods 2.2 Method Indenter Load F kg Load F N Load Factor 0.102 x F/D2 Hardness Range HBW* Material HBW 1/30 1 mm 30 kgf 294.2 N 30 95.5-653 . The Vickers hardness testing method offers advantages such as a small indentation size, accurate hardness measurements,

5.1 For advanced ceramics, Vickers indenters are used to create indentations whose surface-projected diagonals are measured with optical microscopes. The Vickers indenter creates a square impression from which two surface-projected diagonal lengths are measured. Vickers hardness is calculated from the ratio of the applied force to the area of contact of the four .

Note 1: The Vickers and Knoop hardness numbers were originally defined in terms of the test force in kilogram-force (kgf) and the surface area or projected area in millimetres squared (mm 2).Today, the hardness numbers are internationally defined in terms of SI units, that is, the test force in Newtons (N). However, in practice, the most commonly used force .This test method is under the jurisdiction of ASTM Committee E-28 on Mechanical Testing and is the direct responsibility of Subcommittee E28.06 on Indentation Hardness Testing. Current edition approved July 30, 1982. Published December 1982. . ASTM E92 Standard test methods for Vickers hardness of metallic materials . The revision incorporates ASTM E92, Test Method for Vickers Hardness of Metallic Materials, into ASTM E384. ASTM E92 is under the jurisdiction of ASTM International Committee E28 on Mechanical Testing. According to Edward Tobolski, chairman of both Committee E28 and Subcommittee E04.05, in the past, hardness testers normally were .

Standard Test Method for Knoop and Vickers Hardness of Materials E0384-10E01 ASTM|E0384-10E01|en-US Standard Test Method for Knoop and Vickers Hardness of Materials Standard E384 Standard Test Method for Knoop and Vickers Hardness of Materials> new BOS Vol. 03.01 Committee E04 $ 117.00 In stockRecall test procedure for determination of the Vickers hardness and Knoop hardness of metallic materials by the Vickers and Knoop indentation hardness principles. Recall whether conversion to other hardness scales or tensile strength values is acceptable, and if . 5.3 Because microindentation hardness tests will reveal hardness variations that commonly exist within most materials, a single test value may not be representative of the bulk hardness. Vickers tests at 1000 gf can be utilized for determination of the bulk hardness, but, as for any hardness test, it is recommended that a number of indents are made and the average .

1.4 This test method covers Vickers hardness tests made utilizing test forces ranging from 9.807 × 10-3 N to 1176.80 N (1 gf to 120 kgf), and Knoop hardness tests made utilizing test forces from 9.807 × 10-3 N to 19.613 N (1 gf to 2 kgf).ASTM E384 is the standard test method for Knoop and Vickers hardness testing. Test loads are as low as 1 gram and as high as 1,000 grams, but are typically in the range of 100 to 500 grams. The Vickers indenter usually produces a geometrically similar indentation at . The Vickers Hardness test (ISO 6507) is used to characterize hardness of various solid materials (metals, ceramics, etc.). A diamond pyramid is pressed against the solid with a certain normal load and the hardness is calculated based on the imprint left on the surface. . Standard Hardness Conversion for metals acc. ASTM E 140 – 97 .

vickers hardness testing procedure

ASTM E384: This standard is for hardness testing on a micro-scale, and therefore includes the Vickers and Knoop hardness tests. ISO 6506: This standard mirrors ASTM E10, as it contains the standard method for measuring the Brinell hardness of metals.

s4 zoom drop test

s5 active drop test

WEBTp Fintech Solutions Ltda. (Brasil) Principais Atividades: Outras Atividades Relacionadas A Intermediação De Credito. Atividades Secundárias: Internet | Emissora De Cartão De .

vickers hardness test astm|vickers hardness testing formula